Hookup Check: Your Ultimate Dating Resource

Explore insights, tips, and advice for modern relationships and hookups.

Crack-Free Prints: Tips for Achieving Flawless Results Every Time

Unlock the secret to flawless prints! Discover expert tips to achieve crack-free results every time and elevate your printing game.

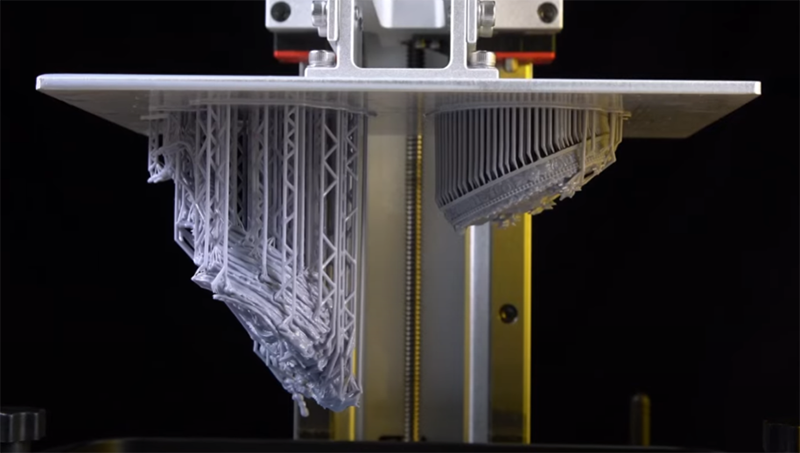

Essential Techniques for Preventing Cracks in 3D Prints

Preventing cracks in 3D prints is crucial for achieving high-quality results. One of the essential techniques is to ensure proper print temperature settings. This involves adjusting the nozzle temperature according to the filament type being used. For instance, PLA typically requires a temperature between 190-220°C, while ABS may need a range of 220-260°C. Additionally, using a heated build plate can help maintain consistent temperatures during the printing process, reducing the chance of thermal stress that leads to cracks.

Another vital approach is to optimize the printing speed and layer height. Slower print speeds allow for better layer adhesion, which is crucial in preventing cracks. Choosing an appropriate layer height, such as 0.1 mm for detailed prints or 0.2 mm for faster results, can significantly impact the structural integrity of the final product. Additionally, regularly calibrating your printer and ensuring the extrusion multiplier is set accurately will help create prints with fewer defects and better overall strength.

For all your Pokémon needs, check out our pokemon shop, where you can find a variety of merchandise, collectibles, and more!

Common Mistakes to Avoid for Flawless Printing Results

When it comes to achieving flawless printing results, many individuals and businesses make common mistakes that can hinder the final outcome. One significant error is the neglect of printer maintenance. Regularly cleaning your printer's nozzles, replacing ink cartridges promptly, and ensuring the printer itself is free of dust and debris can dramatically enhance print quality. Additionally, failing to choose the correct paper type for the job can lead to smudged or faded prints. Different printers are optimized for specific paper types, such as glossy or matte, and using the wrong one can compromise your results.

Another frequent pitfall is overlooking the importance of color management. Many users print without calibrating their monitors or setting appropriate color profiles, which can result in prints that look drastically different from what is seen on screen. To avoid this, it’s crucial to use a calibrated monitor and ensure your software settings match your printer's capabilities. Moreover, always preview your designs before printing to catch any formatting errors. This simple step can save time and resources, helping you attain flawless printing results every time.

How Temperature and Material Choices Impact Print Quality

The relationship between temperature and material choices plays a critical role in determining the overall print quality of a finished product. Different materials, such as PLA, ABS, or PETG, have specific temperature requirements that affect their adhesion properties and extrusion consistency. For instance, when printing with PLA, maintaining the correct print bed temperature can ensure that the layers bond correctly, reducing the risk of warping or layer separation. On the other hand, ABS generally requires higher temperatures both for the nozzle and the print bed to minimize issues such as cracking and poor layer adhesion, which can severely compromise the print quality.

Furthermore, the choice of material can impact not only the mechanical properties of the final print but also its aesthetic qualities. For example, using a high-quality resin at optimal temperature settings can produce prints with smoother surfaces and finer details, making them more visually appealing. Conversely, if the temperature is too low for the selected material, the print may suffer from rough textures and poor detail reproduction. Thus, understanding how temperature and material choices interrelate is crucial for any enthusiast or professional looking to achieve the best possible print quality.